December 2025

Reflection

The rocket is shipped back to our headquarters, and we study the results of launch provided by the avionics, writing and publishing a whitepaper report documenting our results.

November 2025

Launch

After over a year of preparation, our rocket is shipped to Los Angeles, California and launched from the Friends of Amateur Rocketry site in the Mojave Desert. The launch will be livestreamed, and a short film documenting the process of creating such a launch vehicle will be released on our Youtube channel shortly after launch kicking off our second PR cycle.

October 2025

Engine is Tested

The rental of rural property should allow us to finally test our engine in a hot-fire, while containing any shrapnel and minimizing potential damages in the case of a failure. Videos documenting the hot fire will be released, kicking off our first PR cycle. Problems identified with any systems during the engine hot fire will be immediately identified and fixed to in preparation for a launch.

September 2025

Test Stand Construction

As more funding is secured, we will be able to purchase our test stand parts and complete the assembly of the test stand. From there, we will test and refine our electronics subsystem in preparation for our engine hot-fire.

August 2025

Preparation for Manufacturing

A new space was found and finally leased, giving us our first space. We completed the design of the new pump-fed system, complete with pump-mounting sketches and new electrical and flow diagrams. Maytec profiles and tooling was ordered, preparing us for the assembly of the test stand.

July 2025

Engine System Changes

As issues are discovered while designing the pressure feeding system, the engine design is changed to electric-pump-fed, with a solid-state battery being used as the rocket's power source.

June 2025

Frame Material Changes

The design of the test stand frame is switched from steel to aluminum, with the frame now intended to be constructed from Maytec aluminum profiles.

May 2025

Work Resumes

Work on the Guinea Pig rocket resumes, with a flow diagram created, labelling every fitting and visualizing where engine plumbing will be mounted.

April 2025

Sublease Update

Guinea Pig project still on hold. Negotiations with the small business owner fail, and a search for another space to lease beigns.

March 2025

Work is Paused

The team begins to get busy with schoolwork, and the Guinea Pig rocket is put on hold.

February 2025

Test Stand Electronics

The design of the engine test stand continues, with sensors and electronics integrated into the system.

January 2025

Stress Simulation

Test stand design continues, with structural simulations being conducted to optimize frame design.

December 2024

Design Continues and Fundraising Begins

The design of the engine test stand is continued, and a steel frame is designed in CAD. Donations begin to be recieved.

November 2024

Engine Test Stand Design Begins

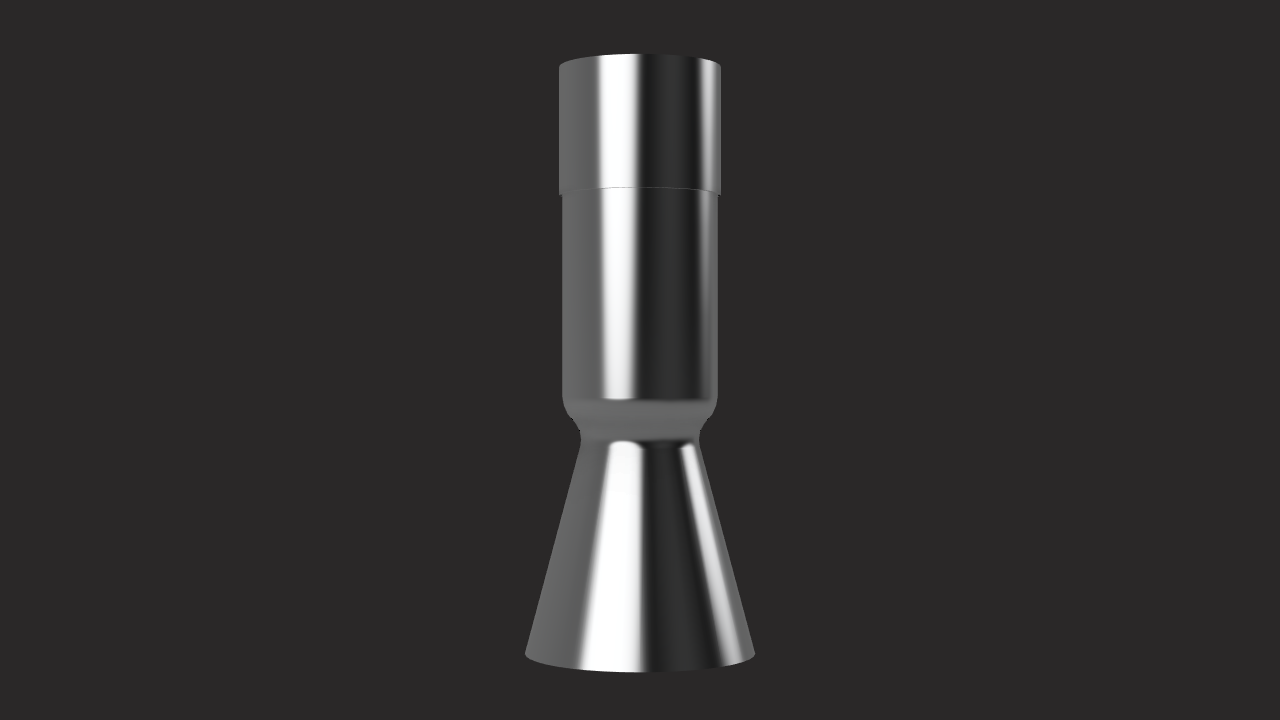

With the completion of the engine 3D print file, we have begun the process of designing the engine test stand. We began talks with a local small business owner to sublease space to operate from. This website was released.

October 2024

Trajectory and Simulation

We coded a simulation of the rocket's ascent to finalize the specifications. In addition, we completely finalized the engine nozzle geometry.

September 2024

Recovery Research and Design

We completed a basic design of our recovery system. This encapsulated the programming of a simulation to predict the rocket's behavior upon descent, which was used to figure out what specific parachutes are needed and how many.

August 2024

Stellar Aerospace is Formed

We formed our group, recruited new members, and begun holding meetings. Since the basic rocket design had been completed by our CEO prior to our group forming, our first step as a group was to begin research on the descent of the rocket and use this to determine the various stresses it will encounter and their magnitudes.